NEWS

DOLLMAR SINERGY

Thanks to chemical and technical expertise, synergistic partnership between the companies of the Dollmar Group allows to meet a variety of needs that include the provision of chemicals, washing and finishing plants, and consulting services.

From the first marketing activities of chlorinated solvents and chemicals, in fact, Dollmar evolved through close contact with different types of industries and their specific problems, expanding its range of expertise through the acquisition of companies specialized in their fields to provide professional solutions and always live up to its customers’ needs.

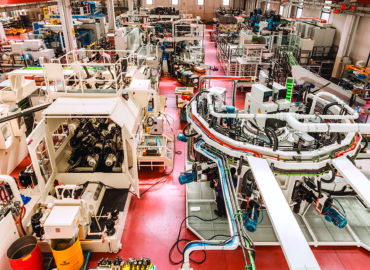

WASHING PLANTS

The field of washing plants and of industrial painting of Dollmar Meccanica soon becamed an industry leader.

PAINTING SYSTEMS

Dollmar Meccanica deals with the design and manufacture of painting systems of Finep line, characterized by automated processes and dedicated to the various stages of pre-treatment, painting and drying of small parts and for the finishing of large manufactures.